EAC Webinar “China Battery Outbound Investment”

In cooperation with China Industrial Association of Power Sources (CIAPS), supervised by the Ministry of Industry and Information Technology of P.R. China (MIIT), EAC conducted a webinar on “China Battery Outbound Investment” on July 10th2020. Over 300 participates from battery manufacturers, battery raw material manufacturers, equipment suppliers, service providers and financial institutes participated.

Besides EAC experts from CATL, TÜV SÜD and Exyte participated as speakers in the Webinar to support Chinese companies along the EV battery value chain to investing in overseas markets.

Targets of the webinar have been:

- How can the Chinese battery manufacturers enter the overseas supply system of multinational automotive OEMs and achieve global expansion?

- How can the Chinese upstream material suppliers and equipment suppliers keep pace with the battery companies to go abroad?

- How can production lines invested by the Chinese companies meet the regulatory requirements and safety standards in Europe?

Key conclusions along the agenda have been:

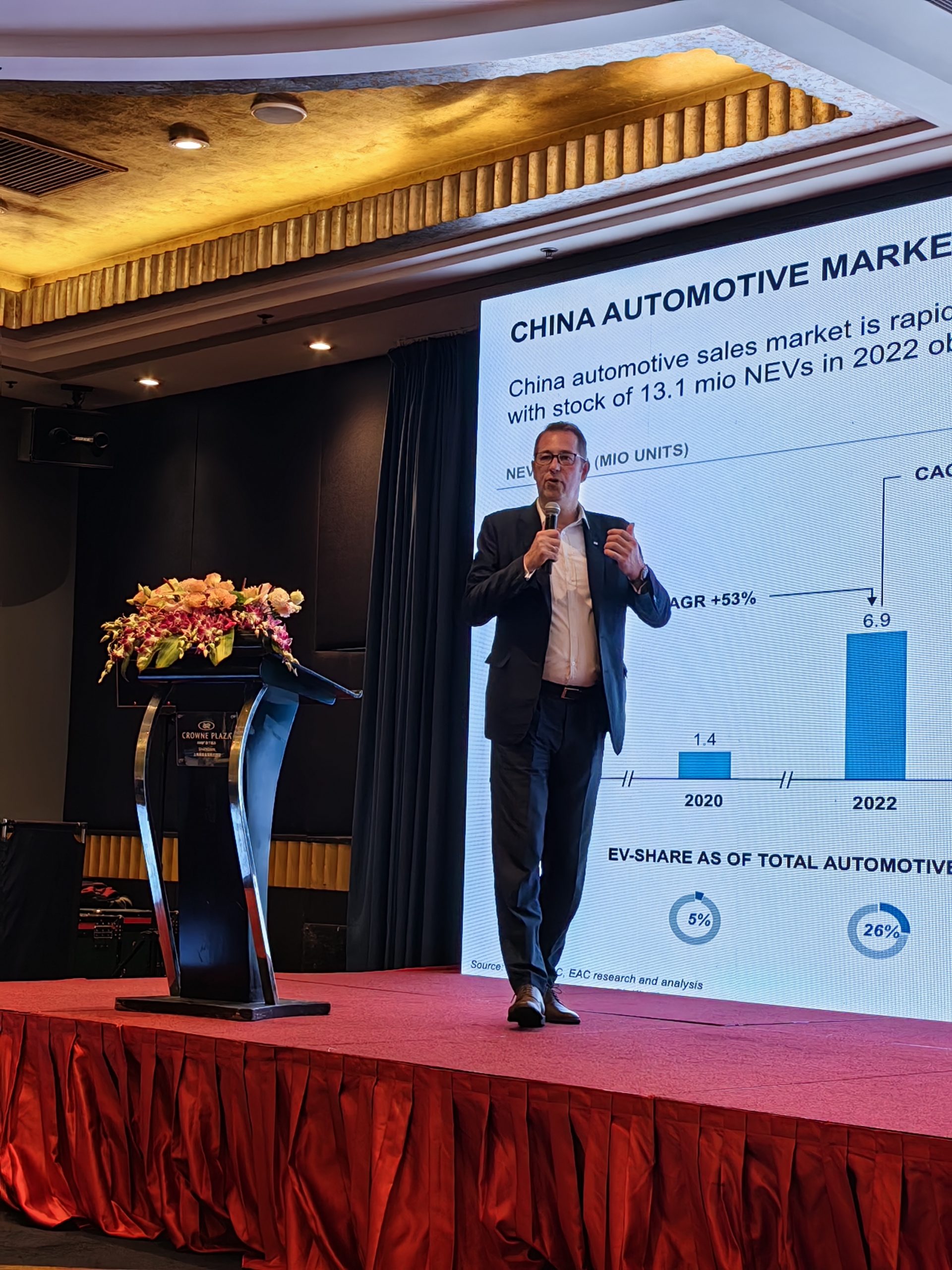

- Global electric car market expected to keep two digital growth and est. to reach ~12 mio. units annual sales in 2025, China is the largest market followed by Europe and USA

- Development of E-mobility in Europe will be positively influenced by governmental legislation and EU government target to improve electric vehicles sales and build up battery value chain capability as well

- LIB capacity will expand more than 3-fold by 2025 – South Korean players have announced aggressive expansion plans in Europe and US; China expected to account for 50-60% of global capacity

- Leading battery manufacturers are dumping huge amount of investments in China, US and Europe to expand capacity and snatch market share in advance, with in total 500 GWh announced

CATL has chosen Germany as the first manufacturing hub in Europe, its key considerations include strong industrial foundation, end-customers proximity and dense atmosphere on R&D and manufacturing. In the future, CATL hopes to cooperate with Chinese raw material suppliers to establish local footprint in Germany and will work closely with international research institutes on technology development.

EAC résumé: Based on our experience from peer industrial projects, investors in Germany need to consider escalating cost in land, equipment, labour, infrastructure, as well as intransparent cost, such as long approval process, complicated environment and safety regulations. The cost of investing in Germany would be at least 2-3 times of investing similar plants in China, from EAC previous project experience.

Targets of the webinar have been:

- How can the Chinese battery manufacturers enter the overseas supply system of multinational automotive OEMs and achieve global expansion?

- How can the Chinese upstream material suppliers and equipment suppliers keep pace with the battery companies to go abroad?

- How can production lines invested by the Chinese companies meet the regulatory requirements and safety standards in Europe?

Key conclusions along the agenda have been:

- Global electric car market expected to keep two digital growth and est. to reach ~12 mio. units annual sales in 2025, China is the largest market followed by Europe and USA

- Development of E-mobility in Europe will be positively influenced by governmental legislation and EU government target to improve electric vehicles sales and build up battery value chain capability as well

- LIB capacity will expand more than 3-fold by 2025 – South Korean players have announced aggressive expansion plans in Europe and US; China expected to account for 50-60% of global capacity

- Leading battery manufacturers are dumping huge amount of investments in China, US and Europe to expand capacity and snatch market share in advance, with in total 500 GWh announced

CATL has chosen Germany as the first manufacturing hub in Europe, its key considerations include strong industrial foundation, end-customers proximity and dense atmosphere on R&D and manufacturing. In the future, CATL hopes to cooperate with Chinese raw material suppliers to establish local footprint in Germany and will work closely with international research institutes on technology development.

EAC résumé: Based on our experience from peer industrial projects, investors in Germany need to consider escalating cost in land, equipment, labour, infrastructure, as well as intransparent cost, such as long approval process, complicated environment and safety regulations. The cost of investing in Germany would be at least 2-3 times of investing similar plants in China, from EAC previous project experience.

Link zum Artikel

Latest

September 18, 2023

„De-Risking China“ vom Chinaforum Bayern e.V.

Juni 22, 2023

ArMiD & EAC – Veranstaltung „Incredible India“

Juni 15, 2023

Quo vadis: Deutsche Industrie der Werkzeugmaschinen in China

Juni 15, 2023

E-Mobilität: Hochspannungsladen als Lösung zur Überwindung von Infrastrukturbeschränkungen